Plant extraction is the main production mode of natural products at present. However, the traditional production mode has many disadvantages.

1. Low content of raw materials and large regional price difference.

2. The plant has a long growth cycle and fluctuates greatly under the influence of market natural factors.

3. The complexity of analogues leads to difficult product purification, waste and large pollution.

4. The wild plant resources have caused serious damage and have been difficult to supply for a long time.

5. According to the latest national catalogue of endangered species, many raw materials are scarce resources and there are legal risks.

In chemical synthesis, because most natural products have complex structures and more chiral centers, inactive or even toxic optical isomers are easy to form in the synthesis process; Moreover, the steps of the synthesis process are cumbersome, the conversion rate is low, the energy consumption is high, and the organic solvent used is easy to cause pollution, which is difficult to meet the needs of industrialization.

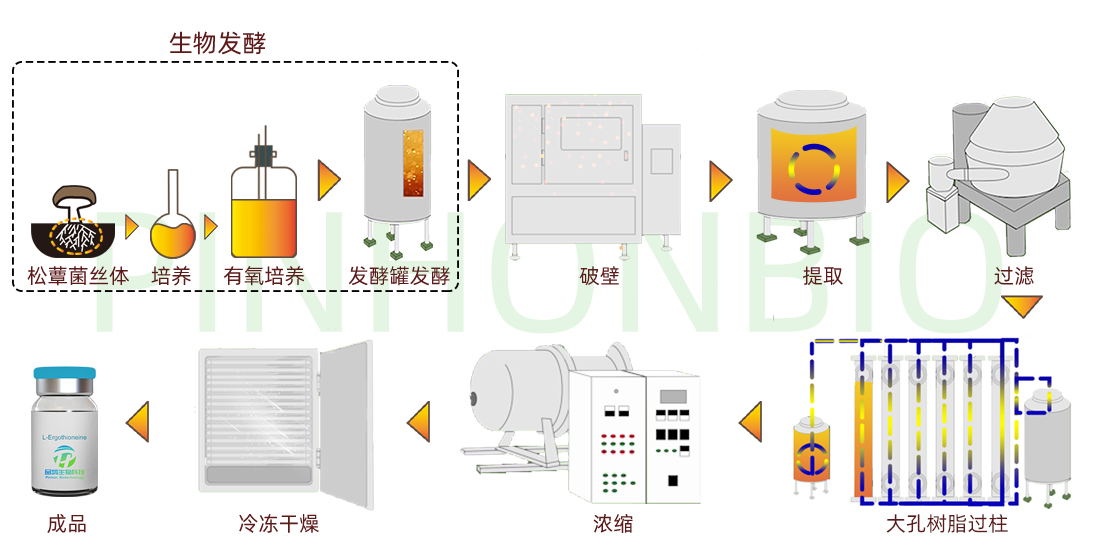

The production of natural products by fermentation has the advantages of short production cycle, not limited by season and raw material supply, single fermentation products, easy separation and purification, and easy to realize large-scale industrial production.

Ergotioneine (ERT) is known as ergotioneine 2-mercapto-histidine-trimethyl internal salt, with a molar mass of 229.3, is a colorless and tasteless natural amino acid. In 1909, tanret C first isolated ergothioin from ergot (sclerotia formed by a fungus parasitic on rye, a gramineous plant). Ergothioin mainly exists in some bacteria and fungi and cannot be synthesized by animals themselves. The human body itself cannot synthesize ergotriene.

(1) It has the advantages of less steps, short time-consuming, simple operation, high yield and high purity of the product. In addition, ergot thioin products with various purity can be prepared according to different application needs.

(2) The extraction process of ergotathione in mycelium only uses water as extraction solvent instead of organic extraction solution with low boiling point, and no inorganic chemicals and petrochemical reagents are added in the extraction process; (only water and ethanol are used in the whole process - food source)

(3) Ultrafiltration process has no phase change, simple operation and low energy consumption, Low cost, no chemical test, no pollution.

Ergotriene is manufactured by using proprietary biotechnology. After the submerged fermentation of mushroom mycelium, the mycelium fermentation liquid is separated by solid-liquid separation, the mycelium is collected, stirred and extracted Ergothioin is leached from the intracellular part of the mycelium into the extracellular aqueous solution. For solid-liquid separation, collect mycelium and ergotathione aqueous solution respectively. Mycelium can be extracted repeatedly according to the above method. For multiple extraction, combine the extracted ergotathione aqueous solution.

L-ergothionine (EGT) is a rare natural chiral amino acid. It is an important physiologically active substance in organisms. It has the functions of scavenging free radicals, detoxifying, maintaining DNA biosynthesis, normal cell growth, cellular immunity, anti radiation, whitening and anti-aging. It is recognized as a unique and multifunctional cell physiological protective agent, Ergothioin plays an important role in antioxidation and energy regulation. Therefore, ergothioin has broad application prospects in food, cosmetics, biomedicine and other industries.